Knowing the unknown

Durkin Construction Senior Project Manager, Mehdi Heydari, describes much of what his team does as enabling the client to “create more certainty from uncertainty”. This was no doubt the outcome of a $100K+ project carried out for our client at the University of Sydney.

“The university needed to retrofit new ducts to transport compressed air between various locations within a high-tech engineering lab,” explained Mehdi.

“In order to install the new conduit and associated elements, they had to assess the distance between the existing elements, to calculate the available vertical and horizontal clearance.

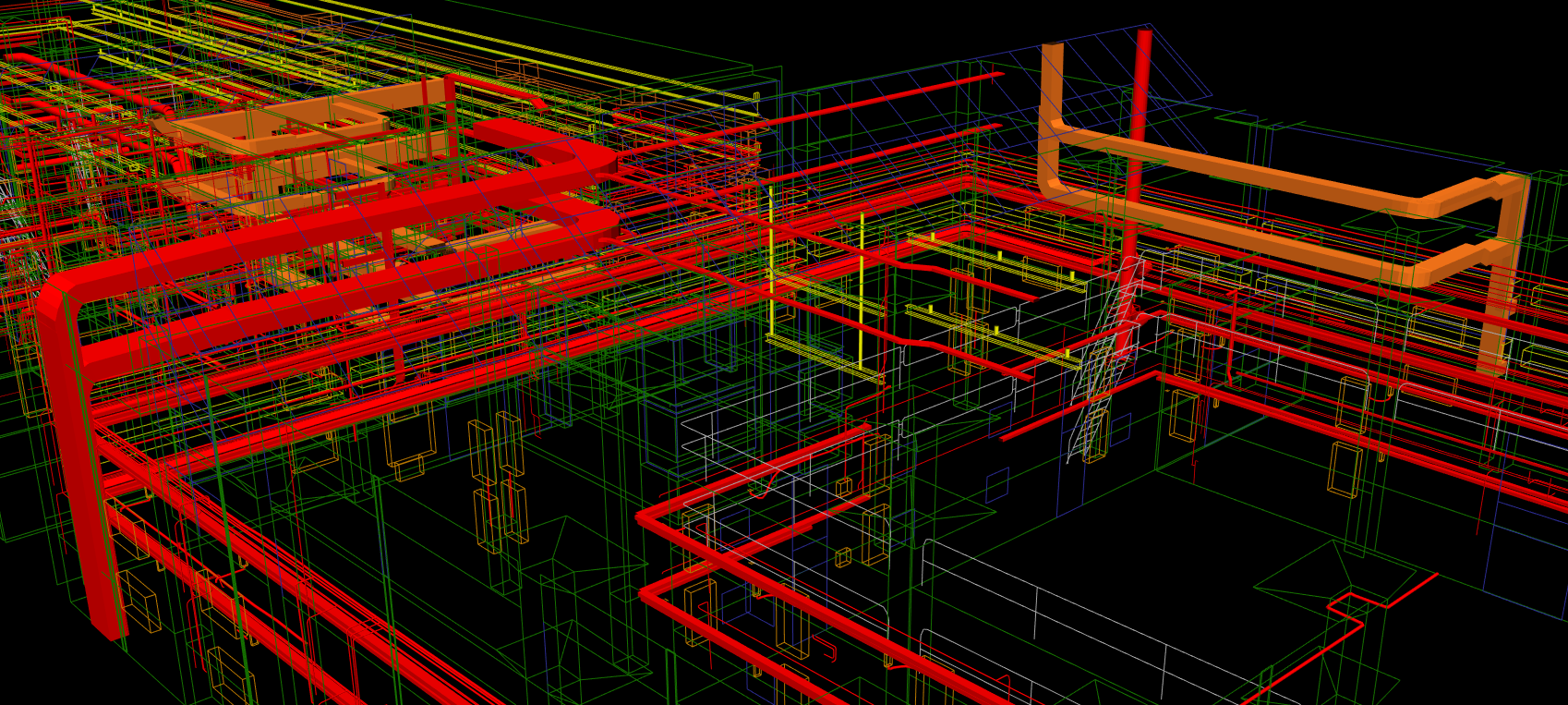

“We were commissioned to produce a Detail Survey and a comprehensive Utility Survey, as well as producing an accurate 3D model of all structural and EMP [electrical mechanical piping] elements. This information formed the basis for the subsequent design and construction work,” added Mehdi

Method:

To achieve the most exact model, 3D laser scanning (LIDAR) and modelling was employed to generate a Point Cloud of the building and a Vectorised model of the existing, internal utilities.

To ensure the highest degree of accuracy, multiple LIDAR scans were completed across a large number of locations, ensuring coverage of all possible angles. Each scan was registered and combined to produce a single, comprehensive vectorised scan. This scan could have been converted to a BIM Model but that was not required in this instance.

The distinct advantage of this method of modelling, over traditional survey practises, is the substantial reduction in time required on-site and the resulting project management, OH&S and cost benefits.

This project required two days on-site, to capture all required scanned data, and ten days in the Durkin office to complete the modelling. A traditional survey would necessitate ten or more days on-site and an additional five days in the office.

Requiring less time on site has multiple benefits for both the client and the contractor. It results in less interruption to onsite operations and lower risk for all parties. Fewer staff are required on-site, reducing cumulative impact and requiring less time on duties such as inductions. Because all data has been captured during the onsite survey and is readily accessible in the Durkin office, the process allows for an increase in the number of ongoing quality assurance checks, reducing the need to return to the site to assess accuracy.

In all, the process is significantly more cost-effective, safer, less disruptive and generally more accurate than traditional methods.

Additional Works:

In addition to the retrofitted ducts and piping in the engineering lab, the university also planned to construct an additional facility in an adjacent carpark and connect the two buildings via a pedestrian bridge. To facilitate construction, accurate levels needed to be taken of the existing building and its floors, windows, doorways, etc.

To assist with the planning and construction of the new laboratories, Durkin conducted a Utility Drainage and Topography Survey, concurrently with the LIDAR scans on the existing building.

The 3D LIDAR models of the engineering laboratory’s existing utilities and overall structure were used in the planning phase, to ensure accurate, seamless connectivity with the new building.

All aspects of the project were completed on time and on budget, with high-quality outputs delivered.

Get in touch with us today to discuss how we can help you achieve similar results.